这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

这是测试文本,单击 “编辑” 按钮更改此文本。

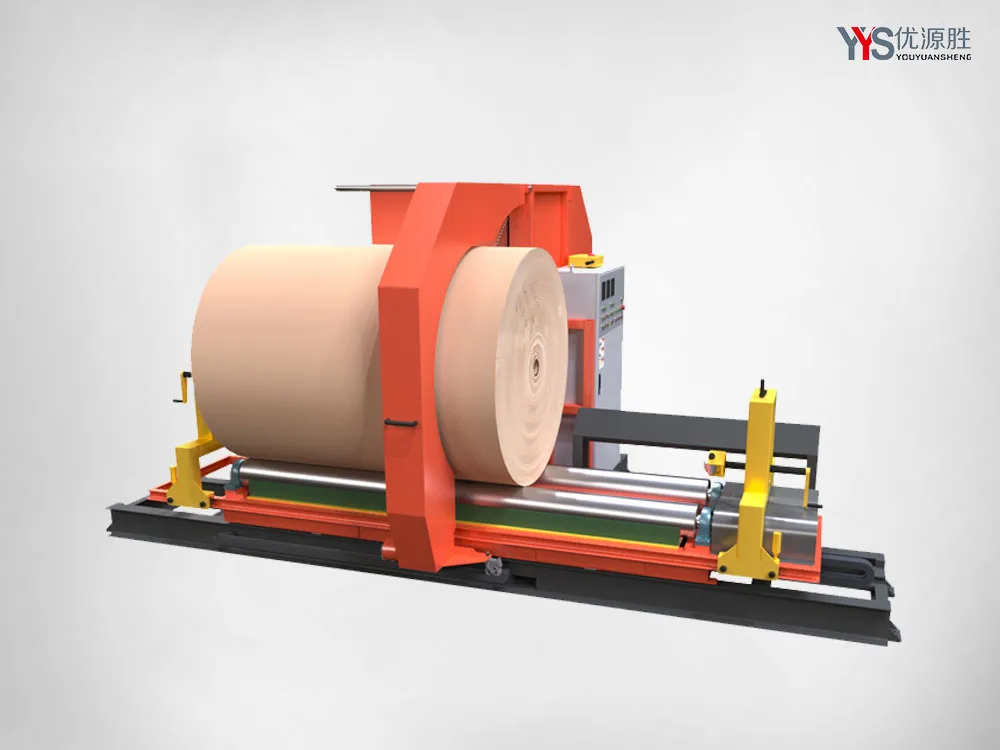

1.35m diameter 2.8m width, save space with high speed, easy to move and install

Paper loss 2mm, little sawdust,high precision, high efficiency, fully automatic

That’s the reason you count on durability and longevity in your recycling equipment investment. Why choose YYS? One simple reason…because We Get That. We understand how critical your equipment is to your business. YYS works hard to exceed your expectations and to make it easy for you to do business with us. When you call YYS for help, our goal is to be focused 100% on helping you get what you need.

Our specialized services are tailored to meet your specifications and on-site requirements. YYS’s specially outfitted fleet enables ready and comprehensive customer care.

All of our equipment is backed by the ongoing maintenance and support of over 100 combined years of industry experience making us able to offer service you can trust from people you know.

Site Planning Assistance: Pre-installation layout optimization for seamless integration into production lines.

Real-Time Logistics Tracking: Guaranteed on-time equipment delivery with dedicated project monitoring.

Onsite Training: Engineer-led demonstrations and staff certification for immediate productivity.

Kunshan Youyuansheng Machinery Co., Ltd. is a specialized industrial solutions provider dedicated to the paper industry, integrating R&D, manufacturing, sales, and mobile cutting services for roll paper saw machines.

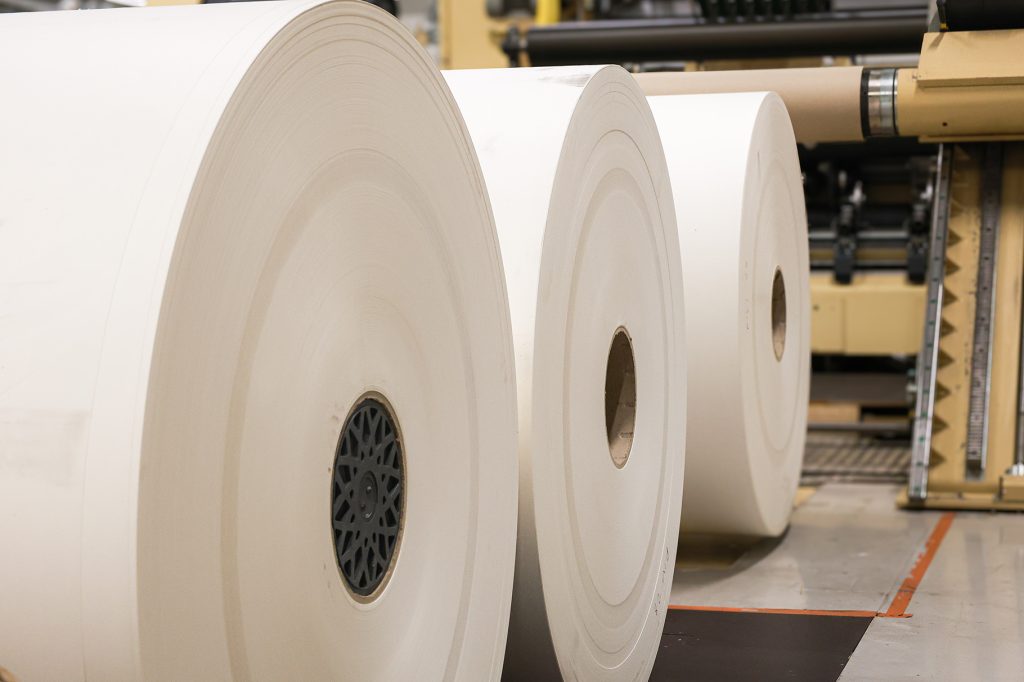

Unlike conventional paper processing equipment (slitting machines, rewinders, sheet cutters), our saw-cutting systems deliver rapid full-roll processing in 5-10 minutes with micron-level precision. Designed for space optimization through resizing capabilities, we tailor machines to cut any diameter (custom ranges: 50cm-3.8m) and width (40cm-1.5m), meeting exact dimensional requirements.

Over a decade, our patented blade technology, premium manufacturing standards, and 24/7 global technical support have established industry leadership. Serving major markets including the U.S., Middle East, Japan, and Europe, we operate under a customer-first philosophy with ISO-certified quality control systems and CE-compliant safety protocols.

Site Planning Assistance: Pre-installation layout optimization for seamless integration into production lines.

Real-Time Logistics Tracking: Guaranteed on-time equipment delivery with dedicated project monitoring.

Onsite Training: Engineer-led demonstrations and staff certification for immediate productivity.

Explore product details for more information. Feel free to contact us.

Kraft paper, corrugated paper, woodfree, etc

Our machine cuts broken paper and modifies roll width efficiently, but it does not alter roll diameter. In contrast, the rewinder adjusts both roll width and diameter, yet it requires intact paper to operate correctly.

The bandsaw machine requires approximately 70 square meters of space, with dimensions of 9 meters in length and 8 meters in width. The circular saw, on the other hand, requires about 20 square meters.

The cutting surface is very smooth. With the band saw, the paper loss is about 2 mm, and with the circular saw, it is approximately 10 mm.

The blade can cut approximately 1,500 rolls before it needs to be replaced. However, it is recommended to sharpen the blade after cutting 300 to 500 rolls, depending on the type of roll paper being cut.

We offer installation guides, video tutorials, and remote assistance. If on-site installation is required, the client will need to cover round-trip airfare, accommodation, and a worker’s daily fee of USD 300.

Yes, we can accept the EXW (Ex Works) price term. However, you would be responsible for handling the export process yourself.

We prefer to T/T, 30% as deposit , 70% balance before loading.

30% prepayment, 60% before delivery, 10% after one month of installation and commissioning.

Yes, we accept L/C. For first – time cooperation, a 30% deposit via T/T is required, with the balance paid by L/C at sight.

We usually prefer TT for first – time cooperation. If LC is necessary, a 30% TT deposit + balance by LC at sight is needed. DP isn’t recommended.

Our standard practice is to require a 30% deposit upfront and the remaining 70% before shipment. This arrangement is essential for us to proceed with the order and ensures a secure transaction for both parties.

The delivery time for the circular model is around 20 days, while the band saw model requires approximately 40 to 60 days.

We will truthfully inform you of the reason for the delay and commit to providing discounts on future orders based on the situation.

Yes, we have 1 year warranty, but except

Our product quality is guaranteed. We prioritize reliability. Our products use environmentally – friendly ABS materials and have passed a full set of safety certifications.

As a high-tech enterprise, we can only provide tax – inclusive prices.

The prices of our machines vary by model. The final quotation will be determined based on your specific requirements.

We’ll determine the best price based on your payment method, location, and the suitable model for you.

With over 10 years in exporting paper cutting machines and global industry partnerships, YYS Machinery ensures customer profit protection and rigorous quality control pre – shipment.

Our products are priced higher due to differences in design, material, and build quality. Our equipment is over twice as heavy as our peers’, reflecting superior durability and performance.

Our products are all certified with ISO and CE.

We specialize in manufacturing circular saw/ band saw paper cutting machines, and sawdust balers.

We continuously research the paper cutting machine market, enhance existing models, and develop new products. We’re committed to sharing updates with our customers promptly.

Yes, you can discuss details directly with them.

Automated Safety,

Unmatched Speed

Precision Cuts

Minimum Waste

Resize Any Roll

Maximize Storage

With 12+ years of continuous innovation, YYS Machinery delivers industrial paper roll cutting solutions for global clients.

We offer paper sawing machines, guillotine cutter, slitting rewinder, along with diverse auxiliary equipment, all tailored to your unique requirements.

1.Need to optimize cutting efficiency for large-scale rigid paper rolls?

2.Require certified durable equipment with failsafe operation?

3.Demand customized machine dimensions and slit parameter specs?

4.Expect professional commissioning and guaranteed lifecycle support?

5.Additional requirements? Contact us instantly!